Baking Industry Automatic Sorting Line

Automatic Sorting Line

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

Automatic Sorting Line is an intelligent sorting system designed for modern industrial production. It aims to achieve efficient and accurate product classification and transmission through automation technology. As an important part of the production line, it can significantly improve sorting efficiency and reduce manual intervention, thereby reducing production costs and improving product quality. The system is usually composed of multiple modules, including core units such as material distribution, sorting and packaging, and each module is precisely designed to ensure optimal performance.

Baking Industry Automatic Sorting Line Specifications

| Product Name | Automatic Sorting Line | ||

| Model | KCLL-600A | KCLL-800A | KCLL-1000A |

| Voltage | 380V3N | 380V3N | 380V3N |

| Conveyor Width | 600mm | 800mm | 1000mm |

| Channels | 6 | 8 | 10 |

| Exterior Material | Carbon steel baking paint/SUS 304 | ||

| OEM/ODM | Accept | ||

| Compay Nature | China Manufacturers Suppliers Factory | ||

Baking Industry Automatic Sorting Line Advantage

1. Multifunctional modular design

The Baking Industry Automatic Sorting Line adopts a modular design, including three core components: material distribution system, sorting system and packaging system. Each module can operate independently or work in conjunction with other modules, and can be flexibly configured according to customer needs. For example, in large-scale production, the system can be directly connected to the front-end automated production line; while in small-batch and multi-variety scenarios, it supports manual material delivery mode. This flexibility makes it suitable for a variety of production scales and product types.

2. High-performance conveyor belt

The conveyor belt is one of the core components of the sorting line. It is made of food-grade polyurethane material with excellent wear resistance, corrosion resistance and easy cleaning. Its smooth surface and non-stick product can effectively avoid damage to the surface of baked goods. In addition, the design of the conveyor belt meets food safety standards to ensure the hygiene and integrity of the food throughout the sorting process.

3. Intelligent control

The sorting line is equipped with a fully automatic intelligent control system and realizes simple and intuitive operation through a touch screen interface. Users can monitor the sorting status, adjust parameters and generate production reports in real time through the interface. The system's intelligent algorithm can automatically identify the specifications and categories of different products and classify them according to preset rules, thus realizing unmanned operation.

4. Low noise and high stability

The Baking Industry Automatic Sorting Line has extremely low noise during operation, only about 60 decibels, which meets the environmental protection requirements of modern factories. At the same time, the equipment has a stable structure, stable operation, extremely low failure rate, and can maintain efficient working status for a long time. This high stability is particularly suitable for baking companies that require continuous production.

5. Strong compatibility

The sorting line supports a variety of input methods, including automatic docking with the front-end production line and manual material delivery. This compatibility enables it to adapt to different production process requirements, whether in large-scale production of a single variety or small-batch processing of multiple varieties, it can perform well.

6. Energy-saving and efficient

Thanks to advanced drive technology and optimized energy management system, the sorting line has low energy consumption during operation, saving about 20% of electricity consumption compared to traditional equipment. In addition, the equip ment can complete large-scale sorting tasks in a short time, significantly improving production efficiency.

7. Accurate sorting capability

The sorting system is equipped with high-precision sensors and image recognition technology, which can quickly and accurately identify product features such as shape, color and size. This precise sorting capability is particularly suitable for products with large appearance differences in the baking industry, such as biscuits, cakes and bread.

8. Easy maintenance

The key components of the equipment are all standardized and easy to disassemble and replace. For example, the conveyor belt and sensor module can be replaced in a few minutes without professional tools. This design greatly reduces the difficulty and time cost of maintenance.

9. Hygiene and safety

The design of the sorting line fully considers the special needs of the food industry. All parts that come into contact with food are made of non-toxic and harmless materials and meet international food safety standards. In addition, the equipment is equipped with multiple safety protection devices, such as emergency stop buttons and overload protection functions, to ensure the safety of operators and equipment.

10. Beautiful appearance design

The overall appearance of the sorting line has been carefully designed with smooth lines and compact structure. It is not only practical, but also adds a sense of modernity to the workshop. Its modular layout is also easy to install and expand, suitable for various plant environments.

1. Biscuit production

In biscuit production, the sorting line can sort biscuits according to shape, size and color to ensure that the product specifications of each batch are consistent. Its high-precision sorting capability is particularly suitable for processing biscuits with complex shapes, such as animal-shaped or letter-shaped biscuits.

2. Bread and cake processing

For larger baked products such as bread and cake, the sorting line can sort them according to weight or appearance characteristics to meet the needs of different customers. For example, bread is divided into family packs and retail packs according to size.

3. Frozen baked goods

In the production of frozen baked goods, the sorting line can quickly sort semi-finished or finished products and send them to the packaging stage to ensure that the product maintains stable quality in a low-temperature environment.

4. Snacks

The sorting line is widely used in the sorting and packaging of snacks such as potato chips, nuts, and puffed foods. Its efficient sorting capability can significantly increase the production capacity of the production line while ensuring the consistency of product appearance.

5. Customized production

For enterprises that need customized orders, the sorting line can flexibly adjust the sorting rules and quickly switch between different product specifications and packaging forms to meet the personalized needs of customers.

6. Multi-variety small batch production

In the multi-variety small batch production scenario, the sorting line supports manual material delivery mode and can quickly switch between different product types, thereby improving production flexibility. This feature is particularly suitable for production needs during seasonal products or promotional activities.

7. Logistics and warehousing

In addition to the food industry, the sorting line can also be used in the logistics and warehousing fields to classify and distribute packages of different specifications. Its intelligent control system can quickly process a large number of orders and improve delivery efficiency.

Baking Industry Automatic Sorting Line Maintenance

1. Regular cleaning

It is recommended to clean the conveyor belt and sensor every day, using warm water and neutral detergent to remove surface residues. After cleaning, wipe it dry thoroughly to prevent water accumulation from causing rust or breeding bacteria. Especially in food processing environments, the cleaning frequency can be adjusted according to the production cycle.

2. Lubrication inspection

Check the lubrication of bearings, chains and other moving parts once a month, and add an appropriate amount of food-grade lubricant to reduce friction. Excess oil stains should be cleaned up in time after lubrication to keep the equipment clean.

3. Fastener inspection

Check whether fasteners such as bolts and nuts are loose every quarter to ensure that the equipment structure is stable. Loose parts may cause unstable operation of the equipment or even cause failures.

4. Electrical system maintenance

Regularly check the control panel and cable connectors to ensure that there is no looseness or damage. If any abnormality is found, contact professional technicians for repair in time.

5. Wear detection

Carry out a comprehensive inspection of key components such as conveyor belts, guide rails and sensors every year to observe whether there is excessive wear or deformation. If necessary, damaged parts should be replaced in time.

6. Calibration and debugging

Equipment calibration should be performed at least once a year, including the adjustment of parameters such as sensor sensitivity and sorting speed, to ensure that the equipment is always in the best working condition.

7. Operator training

Regularly organize operators to participate in equipment use and maintenance training to ensure that they are familiar with the equipment's operating specifications and daily maintenance points, thereby reducing the risk of human operating errors.

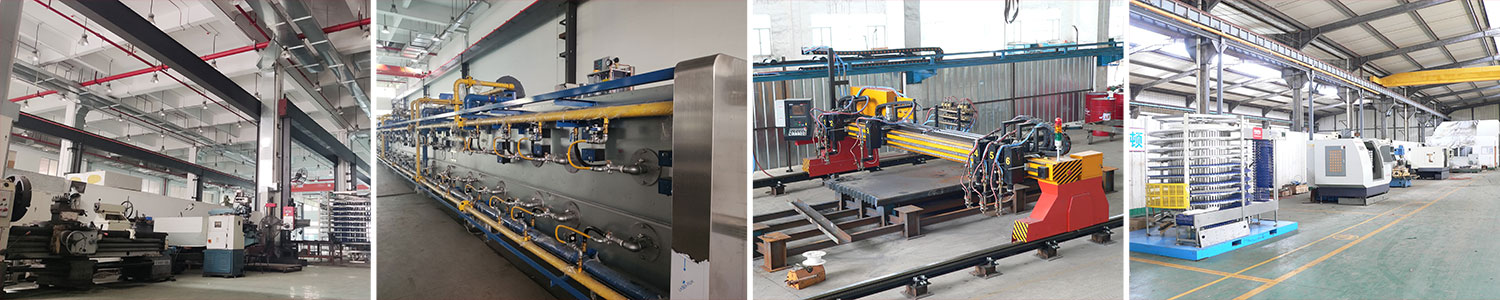

Production Environment

With advanced equipment and skilled personnel, we provide customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Engineering Cases

We deeply understand that every customer has diverse needs. Therefore, we provide professional customized baking solution services, tailoring baking engineering machines according to customers' actual requirements. From the functional configuration to the design of the machine, we fully consider customers' personalized needs to ensure that every machine becomes a proud product for the customer.

Application Scenarios

KC-SMART provides cutting-edge solutions tailored to the baking industry. Our intelligent mechanical equipment is widely used in the production of diverse baked goods, including bread, mooncakes, cookies, and cakes.

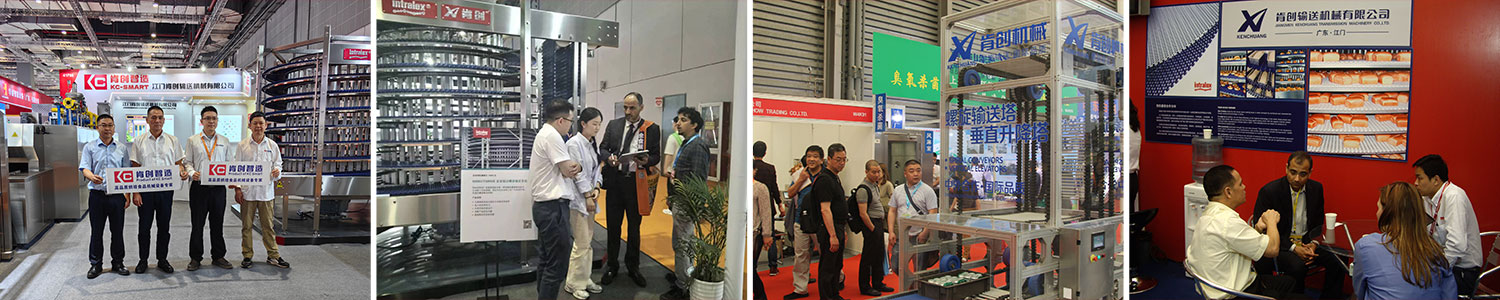

Exhibitions

At KC-SMART, we actively participate in industry-leading trade shows to showcase our advanced intelligent mechanical equipment for the global baking industry. These exhibitions provide an excellent platform to connect with clients, discuss their specific needs, and demonstrate our solutions for powder transportation, mixing, fermentation, baking, cooling, and material handling.

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

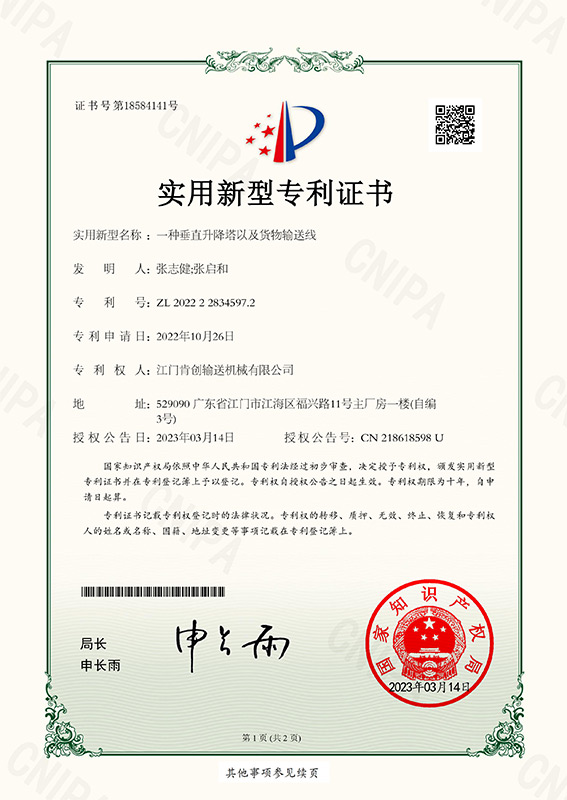

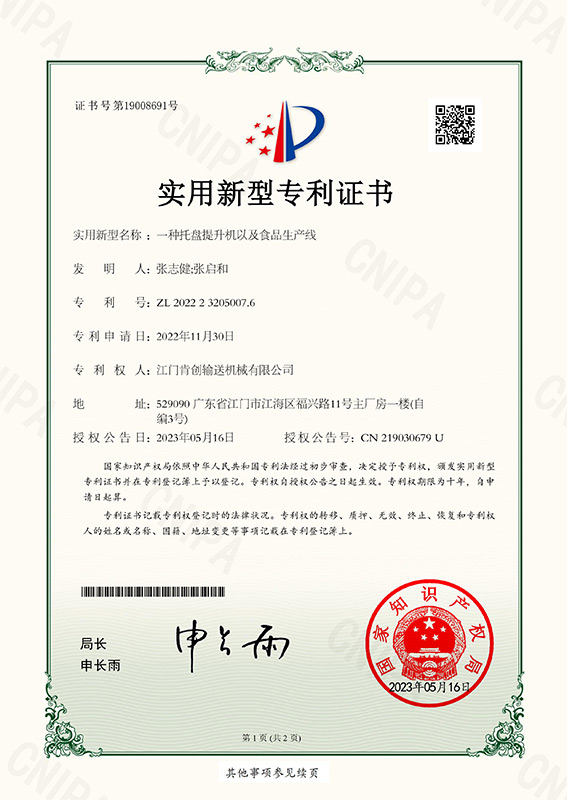

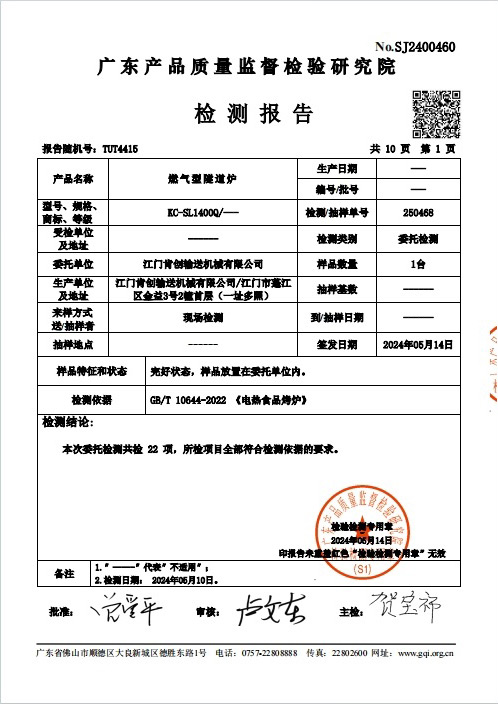

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.