Bread Cooling Spiral Conveyor Systems

Spiral Conveyor Cooling Tower

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

A cooling spiral conveyor is a type of conveying equipment used in food production processes, primarily to extend product transport time on the production line and enable temporary storage or cooling. By ascending or descending in a spiral, it increases product dwell time during transport, thereby achieving cooling or buffering. This equipment is commonly used in the baked goods industry, such as in the production of mooncakes, hamburgers, and cakes. It utilizes natural or forced convection to lower product temperature, ensuring it remains at an appropriate temperature during subsequent processing or packaging. Equipment parameters such as the number of layers, layer height, diameter, and height can be customized to meet varying production capacity and space requirements.

Bread Cooling Spiral Conveyor Systems Parameters

| Product Name | Spiral Conveyor Cooling Tower | |

| Model | KCLX-01 | KCLX-02 |

| Voltage | 380V3N | 380V3N |

| Power | 3kW | 6kW |

| Conveyor Material | POM/Stainless steel | POM/Stainless steel |

| Rotational Speed | 1.6/2.0/2.2/2.5/3.2 | 1.6/2.0/2.2/2.5/3.2 |

| OEM/ODM | Accept | |

| Compay Nature | China Manufacturers Suppliers Factory | |

Bread Cooling Spiral Conveyor Systems Features

1. Food-Grade Materials:

The Bread Cooling Spiral Conveyor System's frame is constructed of 304 stainless steel, while the conveyor belt is made of high-strength, food-grade plastic. This material combination is wear-resistant, corrosion-resistant, easy to clean, and non-sticky, ensuring product surface integrity. The conveyor belt is FDA-approved, ensuring food safety. For example, the corrosion resistance of 304 stainless steel enables long-term use in humid food production environments, while the food-grade plastic conveyor belt effectively prevents product contamination during transport.

2. Versatile Design:

The Cooling Spiral Conveyor offers a variety of functions, enabling not only cooling of high-temperature products but also storage and fermentation (fermentation functionality is customizable). For example, the cooling function allows baked goods to quickly cool down after leaving the oven, preventing overheating that could affect subsequent processing or packaging. Furthermore, the system's versatility allows for flexible use at different production stages, improving overall production line efficiency.

3. Intelligent Control:

The Cooling Spiral Conveyor utilizes a fully automatic intelligent control system with a simple and intuitive touchscreen interface. This design not only improves operational convenience but also ensures efficient and energy-efficient operation. For example, the intelligent control system automatically adjusts conveyor speed and cooling time based on product temperature and production requirements, achieving precise temperature control and energy conservation.

4. High Stability:

The Cooling Spiral Conveyor combines manual and automatic operation modes, offering easy control, quiet operation, high stability, and a low failure rate. Its stable operation ensures production line continuity and reduces production interruptions caused by equipment failure. For example, the low failure rate effectively reduces repair costs and downtime, thereby improving production efficiency.

5. Customizable Design:

Bread Cooling Spiral Conveyor Systems offer comprehensive customization options, including external dimensions such as the number of tiers, tier height, tower diameter, and tower height. This customized design ensures seamless integration into the customer's production line and meets unique space and capacity requirements. For example, the number of tiers and height can be adjusted to optimize space utilization and production efficiency based on the customer's production capacity and factory space.

6. Energy Efficiency:

The Cooling Spiral Conveyor is designed with energy efficiency and high efficiency in mind. Its 3kW and 6kW motor power options allow for flexible selection based on production needs, ensuring the equipment meets cooling requirements while minimizing energy consumption. For example, during low-load conditions, a lower-power motor can be selected for energy-efficient operation.

7. Versatile:

The Cooling Spiral Conveyor is suitable for cooling or buffering a wide range of products, from mooncakes and hamburgers to baked goods like cakes. Its wide range of applications makes it an indispensable piece of equipment for food production lines. For example, the conveyor belt and spiral structure adapt to the transport needs of products of varying shapes and sizes, ensuring product stability during transport.

8. Compliance with Industry Standards:

The Cooling Spiral Conveyor is designed and manufactured to industry standards, including a 380V 3N voltage and multiple speed options (1.6/2.0/2.2/2.5/3.2), ensuring stable operation in diverse industrial environments. For example, the 380V3N voltage standard is suitable for most industrial power environments, while the diverse speed options can be adjusted according to the cooling needs of the product to achieve the best cooling effect.

1. Baked Goods Cooling:

Bread Cooling Spiral Conveyor Systems are widely used in baked goods production, primarily for cooling bread, cakes, mooncakes, and other baked goods. After leaving the oven at high temperatures, baked goods need to be cooled quickly to prevent sticking and deformation. The spiral conveyor structure allows the product to cool naturally during conveyance, extending the cooling time and ensuring a uniform temperature drop for subsequent packaging or processing.

2. Food Buffering and Temporary Storage:

Cooling Spiral Conveyors can be used for temporary buffering and temporary storage of food. On the production line, when subsequent processes experience a brief lull, the equipment can serve as a buffer, temporarily storing product to avoid backlogs. Its multi-layered spiral structure increases storage space while maintaining product stability and sanitation during conveyance.

3. Food Fermentation:

Bread Cooling Spiral Conveyor Systems can also be used for food fermentation (customizable fermentation environments are required). During the fermentation process, the multi-layered structure provides a stable storage space for the fermenting product, while regulating the conveying speed and ambient temperature to ensure uniform and consistent fermentation. This versatile design provides greater flexibility for food production.

4. Automated Production Line Integration:

The Cooling Spiral Conveyor seamlessly integrates into automated production lines. Its customizable number of layers, height, and diameter allow it to be adjusted to the production line's space and capacity requirements. Its fully automatic intelligent control system works in tandem with other production equipment to ensure an efficient and continuous production process.

5. Multi-Industry Applicability:

The Cooling Spiral Conveyor is suitable not only for the bakery industry but also for the production of foods such as hamburgers and sandwiches. Its versatility allows it to meet the cooling, buffering, and conveying needs of a wide range of foods. Its diverse design and flexible customization options make it an ideal auxiliary equipment for the food processing industry.

Bread Cooling Spiral Conveyor Systems FAQ

1. Can the dimensions of your spiral conveyor cooling tower be customized to fit specific production requirements?

Yes, our spiral conveyor cooling tower offers full customization options for its outer dimensions, including the number of layers, layer height, tower diameter, and tower height. This ensures that the tower seamlessly integrates into your production line and meets your unique space and capacity needs.

2. How versatile is your spiral conveyor cooling tower in terms of its applications?

Our spiral conveyor cooling tower is highly versatile, offering a one-machine-multi-use functionality. It can be utilized for product cooling, storage, and even fermentation processes. This flexibility allows you to optimize your production line and streamline multiple processes within a single unit.

3. What measures have been taken to ensure the stability and low failure rate of your cooling tower?

Stability and reliability are core design principles of our spiral conveyor cooling tower. We employ robust construction materials and advanced engineering techniques to ensure that the tower remains stable during operation, even under heavy loads. Additionally, rigorous testing and quality control measures are in place to minimize the risk of failures, resulting in a low failure rate and high uptime.

4. Can the cooling process be customized to suit different food products or production requirements?

Absolutely, the cooling process in our spiral conveyor cooling tower can be tailored to meet the specific needs of various food products and production requirements. We can adjust factors such as airflow, temperature, and humidity to optimize the cooling process for your specific products, ensuring optimal quality and shelf life.

5. How does the spiral conveyor design contribute to the efficiency of the cooling tower?

The spiral conveyor design of our cooling tower enhances efficiency in several ways. Firstly, it allows for a continuous and gentle movement of products through the tower, minimizing damage and ensuring even cooling. Secondly, the spiral configuration maximizes the surface area exposed to the cooling air, accelerating the cooling process. Lastly, the design promotes efficient use of space, allowing for a higher capacity within a compact footprint.

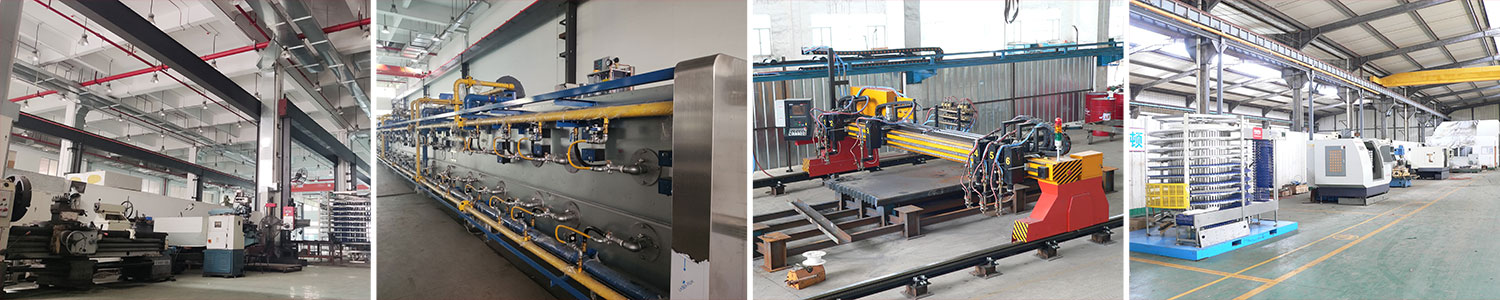

Production Environment

With advanced equipment and skilled personnel, we provide customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Engineering Cases

We deeply understand that every customer has diverse needs. Therefore, we provide professional customized baking solution services, tailoring baking engineering machines according to customers' actual requirements. From the functional configuration to the design of the machine, we fully consider customers' personalized needs to ensure that every machine becomes a proud product for the customer.

Application Scenarios

KC-SMART provides cutting-edge solutions tailored to the baking industry. Our intelligent mechanical equipment is widely used in the production of diverse baked goods, including bread, mooncakes, cookies, and cakes.

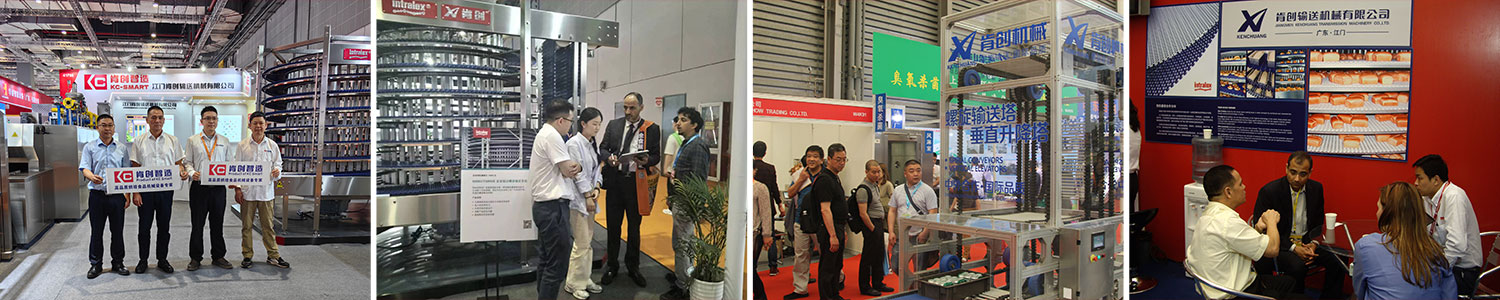

Exhibitions

At KC-SMART, we actively participate in industry-leading trade shows to showcase our advanced intelligent mechanical equipment for the global baking industry. These exhibitions provide an excellent platform to connect with clients, discuss their specific needs, and demonstrate our solutions for powder transportation, mixing, fermentation, baking, cooling, and material handling.

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

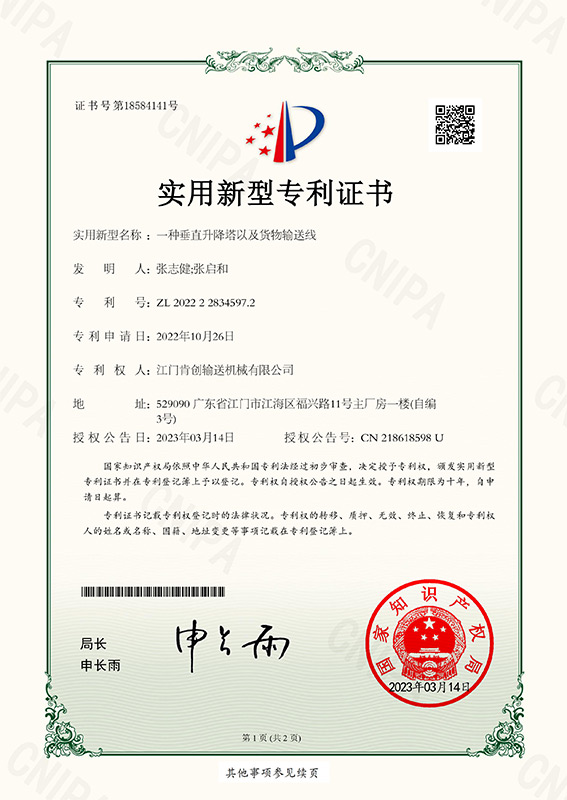

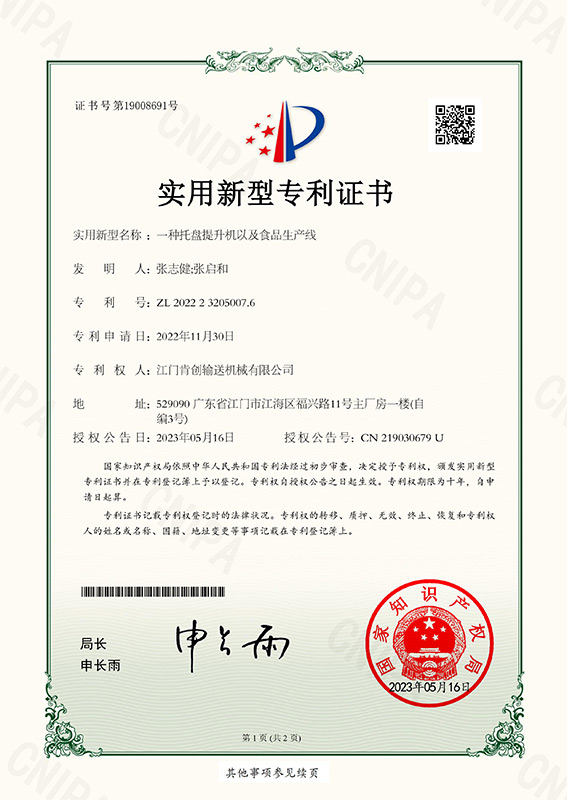

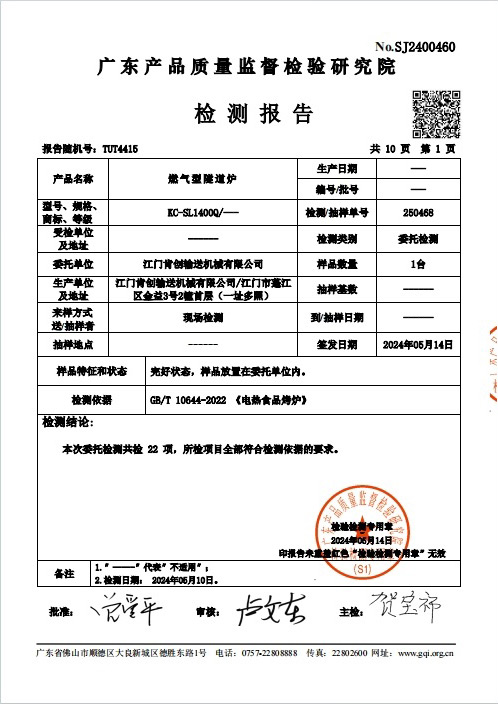

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.